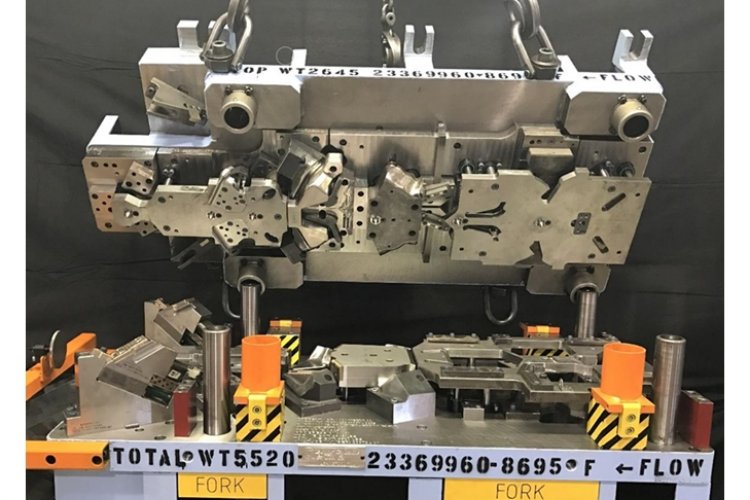

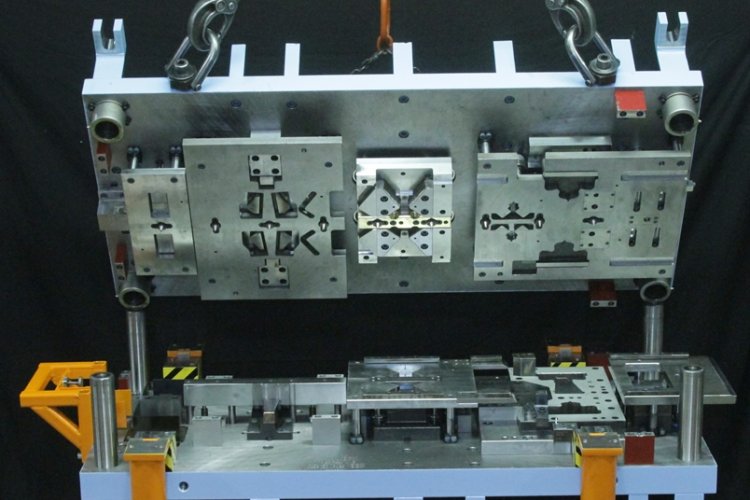

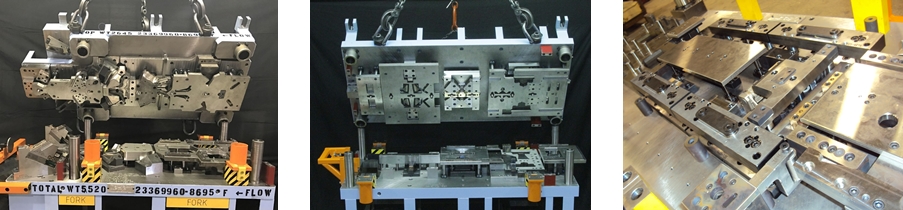

Ashing Machine and Tool specializes in precision progressive stamping dies. Our progressive dies are built to your specifications, making sure to make your final part is produced exactly the way you need it.

No matter how complex the project, our team of engineers will design tooling to achieve even the most difficult and demanding stamping press applications. With our state of the art design processes and technology, we are able to manufacture progressive dies are designed to stay in operation with fewer breakdowns and fewer maintenance needs than other dies.

Our progressive stamping dies are built for easy component replacement and can be designed to handle almost any material including steel, aluminum or other specialty alloys. With design options available in a wide variety of coil widths and progressions, we can optimize for best material usage.You can be assured that your die will work as promised, guaranteed.

(View our project gallery to see samples of our progressive die work.)

Progressive Dies

Ashing Machine & Tool uses a 4 point process to qualify and deliver every progressive die we manufacture. The four steps of every project are followed in great detail to ensure great results for our customers.

Our 4 step process includes:

- Quotation

- Design

- Build

- Support

Progressive & Stamping Die Quotation

Every progressive die and stamping die project officially begins with a quote but we make sure our qualification process before an official quote is issued is the best in the industry. We make sure that our quote will deliver what you need and what you expect out of the project. Our quotes will also be quick and accurate with turnaround quote time in most instances within 2 business days or less.

Progressive Stamping Die Design

The progressive die design system we use ensures that our dies are engineered correctly and to specifications every time. This process enables us to quickly and efficiently design your progressive dies to meet critical deadlines and ensure critical steps and oversites are not skipped or mismanaged during the design and signoff stage of the build.

Die Build

Whether it's a line die, steel stamping die or some other types of metal stamping die our build times adhere to the project timelines and we deliver on time. We also thoroughly test each and every die making sure implementation is as smooth as possible and implementation is as seamless as possible.

Support

Ongoing support, follow-up and after the sale service is one of the hallmarks of Ashing Tool's commitment to its customers. Being a tool and progressive die maker for over 30 years shows our stability and longevity giving customers the confidence that we will be here for the whatever comes down the road. Also, our wide array of capabilities can deliver almost any customization or feature needed. Whether additional customizations are needed, technical troubleshooting after implementation or just advice on future enhancements and maintenance, we are here to help.